Scope, Budget, and Change Control: Keeping Fire Rebuilds on Track

By Joy Line Homes California

Rebuilding after wildfire asks for more than good design. It asks for discipline. Families in Los Angeles, Ventura, Santa Rosa, Napa, and Paradise want a clear scope, a predictable budget, and a schedule that finishes when promised. Joy Line Homes uses modular precision and a simple change control system to keep projects steady from day one. The result is less drift, fewer surprises, and a quicker path back to life on your land.

Scope and budget are not just documents. They are a daily rhythm. When decisions are grouped, options are curated, and records are clean, the team moves with confidence. This article explains the Joy Line method so owners know how the plan stays firm even when the calendar is full and emotions are high.

Start with a Single Source of Truth

Every project begins with a single sheet that summarizes the work. Model, plan family, foundation choice, ADU option, exterior package, interior package, and site scope live in one place. A link at the top opens the digital binder. The same sheet lists the address, parcel number, and contact for the lender and carrier. When anyone has a question, they start here. This single source reduces phone calls and keeps answers consistent across the team.

Owners receive a printed copy at kickoff. Inspectors see a copy during the first visit. The lender and adjuster receive the PDF. Everyone reads the same story and the project gains pace.

Scope that Fits the Mission

Scope is a promise. Joy Line organizes scope in three groups. Factory work that creates the modules. Site work that prepares the parcel. Finish work that joins the two. Each group carries a checklist with lines that match invoices and inspections. If a line is not on the list, it does not sneak into the budget. If a new need appears, it is logged as a change request and priced before work begins.

In Santa Rosa, scope may favor slab on grade and short trench runs. In Los Angeles hillsides, raised platforms and route studies enter the list. In Paradise, helical piles and compact picks are common. The sheet changes by city, yet the structure remains the same so owners can compare apples to apples as they make choices.

Budget Built on Real Assemblies

Budgets fail when they rely on allowances and guesses. Joy Line prices by assembly. Walls, roofs, eaves, windows, doors, decks, and venting each have a package tied to code and performance. Energy models match the assemblies in writing. WUI details sit beside the numbers. When the city or carrier asks a question, the answer is already visible on the page.

Owners see base cost, selected options, and a modest contingency sized to real risk. The contingency is not a license to spend. It is a shield for unknowns like a small utility relocation or a rock pocket. When contingency is used, the log notes what happened and why. When it is not used, it stays in the owner’s account at the end.

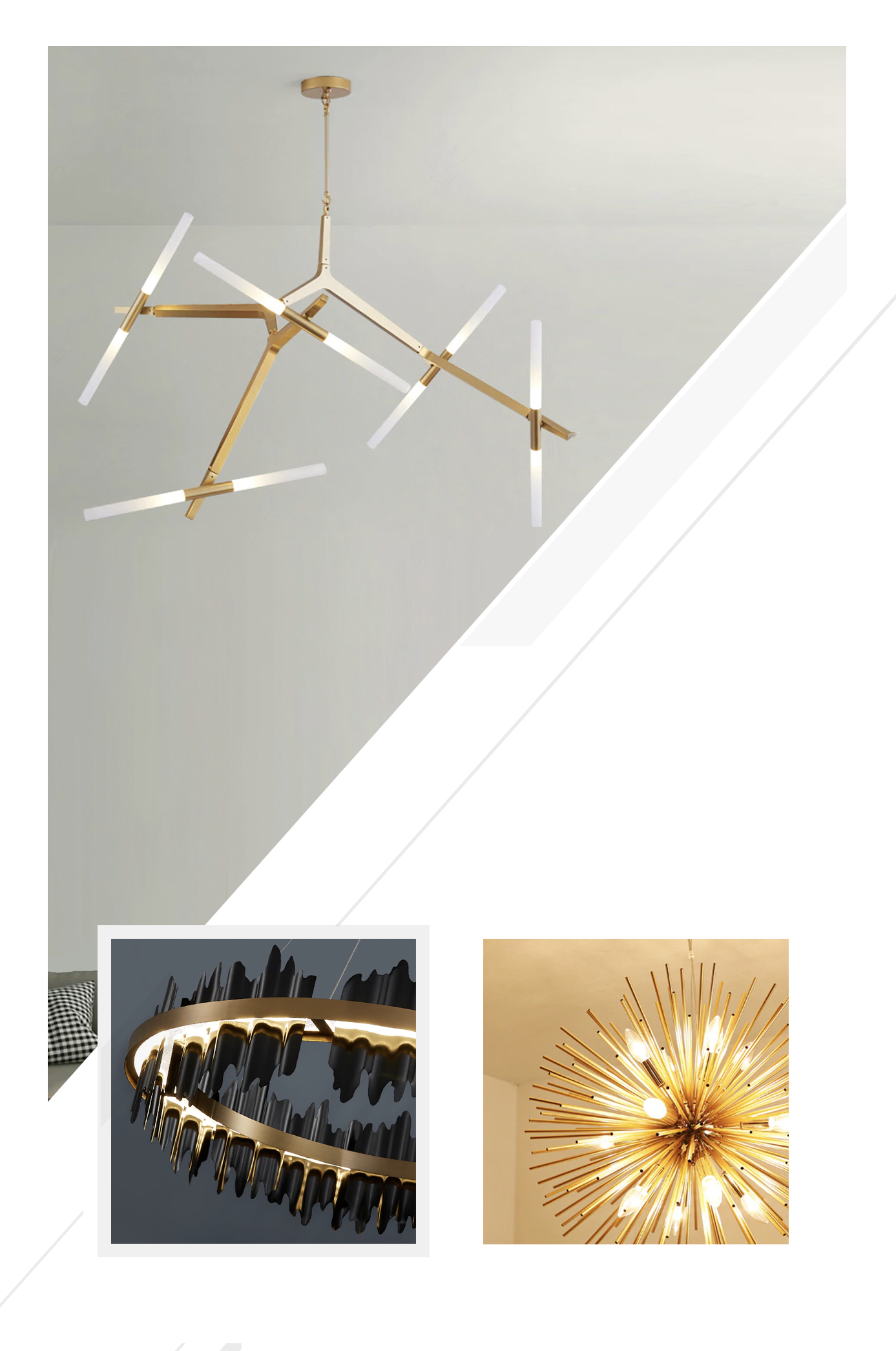

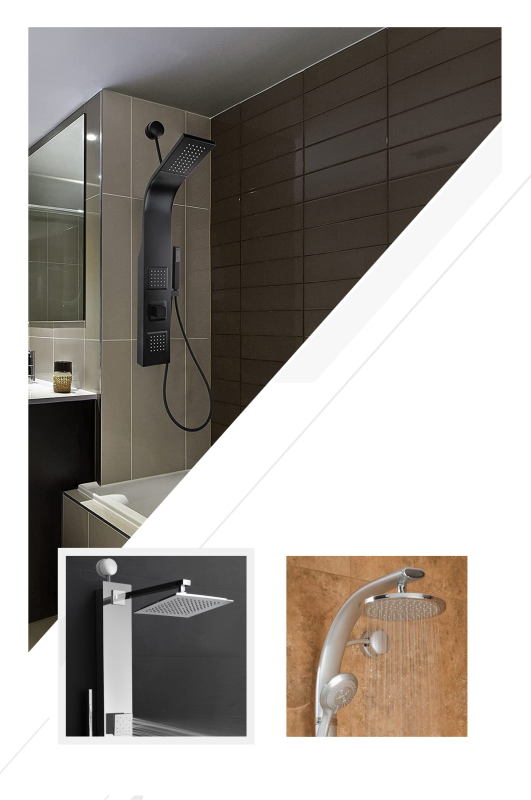

The Option Menu that Prevents Drift

Choice is good when it is curated. Joy Line builds option menus that support comfort and safety without opening the door to endless revisions. Exterior packages meet WUI rules and still deliver a modern look. Interior palettes stay low VOC and easy to clean. Mechanical options align with clean air goals. Owners pick once per category, then the package locks for production. Tidy menus save weeks and protect budget because the team can order with confidence.

Upgrades are clear and priced. A different metal roof profile lists as a line item. Added glazing includes the shade plan that keeps loads steady. Every choice has a reason and a number. No guesswork and no hidden adders.

Change Requests that Respect Time and Money

Change will happen. The key is timing. Joy Line uses a simple form. Describe the request in plain language. Show the drawing or product link if needed. Price the delta. Note the schedule impact in days. Owners approve or decline in writing. The log updates and the team moves on. No hallway decisions. No texts that get lost. This discipline keeps production dates safe and protects lender trust.

After factory release, changes narrow to site items and finish details that do not disturb structural work. The owner knows which door is still open and which door has closed for this cycle. Peace of mind follows that clarity.

Draws that Match Real Milestones

Lenders want proof that money tracks progress. Joy Line pairs draw requests with photo logs and inspection tags. Deposit, factory completion, set day, dry in, and final each carry dated images and notes. The lender sees framing, eave closure, and utility connections without a site visit in many cases. Funds release quickly and the calendar stays on track. The owner sees the same record and feels informed rather than in the dark.

In block groups, three homes may share a single draw rhythm. Vendors and lenders appreciate the order. Neighbors appreciate streets that reopen by dinner on set day.

How We Protect Against Scope Creep

Scope creep arrives through small doors. A fence pushed to the wall. A deck added before grade is set. A window shifted after energy modeling. Joy Line trains the team to ask one question. Does this change fit the mission. If it helps safety, schedule, or comfort, we price it and move forward. If it is a want that can wait, it moves to a future list. The home is delivered on time. The future list becomes a simple weekend project plan that does not slow the certificate of occupancy.

Owners stay in control because they see the trade. Dollars and days are visible. A calm finish beats an endless build every time.

Communication that Works on Busy Weeks

Rebuild weeks can be full. Joy Line keeps messages simple. One weekly update with photos and a three line summary. One dashboard that shows schedule, inspections, and the change log. One channel for decisions so answers do not scatter across apps. When owners need a deeper dive, a short call pairs the dashboard with the binder so everyone sees the same facts. Meetings end with two lists. Done and Next. The project moves.

This rhythm reduces stress. People sleep better when they know what happened today and what will happen next Tuesday.

ADU First to Stabilize Budget

Many families start with an ADU. The ADU carries the same envelope and interior language as the main home. It lands near existing utilities, creates a sheltered court, and returns families to their parcel fast. Rent costs fall. Future income becomes possible. Inspections teach the city the Joy Line method so the main permit moves quicker. The ADU also proves the option set. Owners see finishes in real light before the larger order is placed. Budget risk drops because choices are tested at small scale first.

After move in, the ADU serves guests, family, or a tenant. One decision creates three benefits. Housing, schedule, and cash flow all improve.

City Notes for Cost Control

Los Angeles: Hillside access drives cost. Route studies and raised platforms appear in scope early so they do not surprise the budget. Shaded glass reduces loads and keeps mechanical sizes modest. A calm envelope saves power and money every season.

Ventura: Salt and wind shape hardware and deck details. Coated fasteners and enclosed skirts cost a little more up front and save many small repairs later. Group inspections keep trips and fees down for coastal blocks.

Santa Rosa: Neighborhood lots favor slab speed and short utility runs. Repeating fiber cement packages and gravel ribbons shortens plan review and reduces change orders during exterior work.

Napa: Rural drives make mobilization a cost item. Group trench windows and shared delivery days lower trips. Deep porches cut loads which tightens energy models and keeps equipment small.

Paradise: Disturbed soils ask for helical piles and compact picks. Clear access diagrams prevent wasted mobilizations. Photo logs attached to draw requests keep lenders decisive while many homes rebuild together.

Quality Controls that Prevent Rework

Rework is the enemy of schedule and budget. Joy Line uses factory checklists for pan tests, flashing order, and eave closure. On site, crews follow a short sequence. Foundations verified. Anchors checked. Set day closed to weather. MEP rough with sealed penetrations. Insulation and air barrier confirmed. Exterior finishes complete with deck skirts and fence returns. Each step has photos and labels. When an inspector arrives, the visit is short and the sign off is quick.

Owners feel the benefit in calm weeks and clean invoices. No scramble. No backtracking. Just steady progress to keys.

Insurance and Lender Alignment

Adjusters and underwriters value clarity. Joy Line ties scope lines to claim categories and lender draws. When code upgrades are required, the packet lists the rule, the assembly, and the cost in a single spot. There is no hunting through emails. Questions shrink to minutes. Funds move with the schedule. The owner does not become a messenger between teams because the document answers most questions before they are asked.

When a supplement is needed, the change form references the assembly page and the photo. Decisions land quickly because proof is attached to the request.

Ownership Routines that Protect Value

The budget story continues after move in. Joy Line provides a one page seasonal plan. Sweep the five foot band. Vacuum vent screens. Rinse gutters and splash blocks. Replace filters. Check seals. These tasks cost little and protect finishes and comfort. Small habits are the cheapest insurance and the best way to keep a home ready during hot, windy weeks.

We also leave spare parts lists for filters, bulbs, and touch up materials. When replacements are at hand, small repairs do not turn into delays or service calls. Owners save time and money every season.

Stories that Show the Method

In Los Angeles, a hillside rebuild held its budget by locking the option set before factory release and using a single crane study for a cluster of three homes. In Ventura, corrosion aware edges and a shared inspection day removed repeat trips and fees. In Santa Rosa, repeating slab details and side ribbons kept the exterior on schedule without change orders. In Napa, deep porches and a courtyard reduced loads and allowed smaller equipment that saved thousands. In Paradise, helical piles and compact picks paired with a strict change log to deliver on time during a busy season.

The Joy Line Perspective

Discipline is kindness in a rebuild year. Scope stays clear. Budgets track real assemblies. Changes follow a short form and a calm decision. Draws match visible work. Inspectors and lenders read the same record. Families return to their homes with fewer worries because the plan never lost its shape. That is how Joy Line Homes turns complicated projects into steady weeks and a simple handoff of keys across Los Angeles, Ventura, Santa Rosa, Napa, and Paradise.

About Joy Line Homes

Joy Line Homes builds modular residences and ADUs with clear scope, assembly based pricing, and documented change control. Our process protects budgets, schedules, and peace of mind from first meeting to final walk.

Visit JoyLineHomes.com to request our scope template, option menus, and change request form for your rebuild.

We are based in Santa Cruz County ,

California

Tel: (831) 888-Home

Email: info@joylinehomes.com

Business Hours: 9am - 6pm