Quality Control Delivers Safer, Faster Wildfire Rebuilds

By Joy Line Homes California

Rebuilding after wildfire should not mean starting from scratch in the elements. It should mean precision, calm scheduling, and assemblies that are verified long before they reach your property. That is the promise of Joy Line Homes. Inside our factory partners, every wall, roof, floor, and connection is measured, documented, and inspected so your Los Angeles, Ventura, Santa Rosa, Napa, or Paradise project moves from planning to keys with confidence. Factory quality control is more than a checklist. It is a culture that protects families, budgets, and timelines.

Modular building separates the work that should happen indoors from the work that must happen on site. Weather does not stop interior framing. Materials do not sit in rain or wind. Trades work in dry, well lit bays with consistent tools and oversight. Each station of the line focuses on a specific craft, then signs off to verify that performance and code requirements are met. The result is repeatable excellence that speeds approvals and creates homes ready for California’s Wildland Urban Interface.

A Clean Start: Materials and Moisture Control

Quality begins with dry, straight, and protected materials. Lumber, sheathing, and insulation are stored under cover, then issued to the line in measured lots. Moisture meters confirm readings before panels are closed. If a component exceeds limits, it is set aside, dried, or replaced. Adhesives and sealants are managed by batch and temperature so they cure properly. This discipline is hard to maintain on outdoor sites but standard in the factory. Homes leave the line with tight, clean assemblies that resist smoke, heat, and seasonal movement.

Material waste drops dramatically. Offcuts are sorted and reused where appropriate. Packaging is recycled. Less waste means lower cost and lighter environmental impact without compromising performance or design.

Precision Framing for WUI Zones

In fire country, details save homes. Factory jigs hold studs, joists, and trusses to tight tolerances so window and door openings are square. This matters for fire performance because square openings accept better gaskets, glazing, and seals. Joy Line specifications require continuous load paths, correct nailing patterns, and backing where ignition resistant claddings transition. Fasteners are counted and inspected. Shear panels are labeled and photographed before wraps go on. Inspectors can view that record, which builds trust and shortens review in cities and counties that manage wildfire rebuilds.

Framing teams also prepare for tight air sealing. Corners, rim joists, and complex intersections receive backing and sealant surfaces during framing so later trades can close the envelope cleanly. That planning improves energy performance and reduces smoke infiltration during poor air quality days.

Envelope Integrity: Wraps, Tapes, and Air Seals

Joy Line treats the building envelope as life safety infrastructure. Weather resistive barriers are installed in controlled bays with measured overlaps and roll pressure. Seams are taped by trained crews who follow a documented sequence that includes corner pre wraps and penetration collars. Window flanges are bedded in sealant and taped in the correct order from sill to head. Every opening is water tested before cladding. The goal is fewer paths for heat and embers, less risk of moisture intrusion, and a more stable interior for decades of use.

These methods also boost comfort. Air tightness reduces drafts and noise. Mechanical systems can be smaller and more efficient. When energy modeling for Title 24 is completed, the factory knows exactly what envelope values must be achieved and delivers them repeatably across modules.

Fire Resistant Exteriors that Look Modern

Ignition resistant cladding should not limit design. In the factory, fiber cement panels and laps are cut on accurate jigs so joints align crisply. Metal profiles are hemmed and finished with concealed fasteners where possible. Soffits are enclosed with rated panels and vents that carry ember screens. Eave blocking is installed before closure so there are no gaps that invite ember travel. The exterior reads clean and quiet while meeting Chapter 7A requirements in WUI zones across California.

Roofs receive equal attention. Class A assemblies are built in layers that include underlayment, shielded flashings, and careful transitions at penetrations. Every step is photographed for the inspection log that accompanies your project to the site.

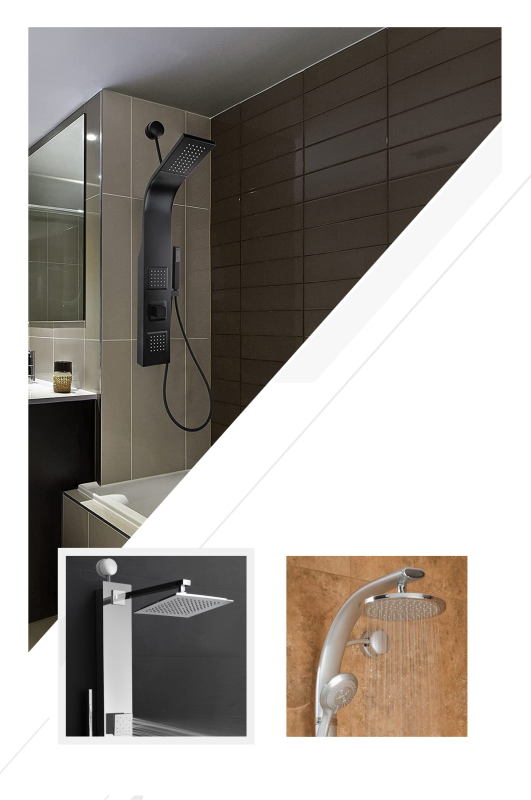

Windows, Doors, and Glazing Checks

Dual pane tempered glass is standard in the fire zones we serve. Factory installation ensures consistent shim spacing, square reveals, and correct fastener schedules. Sill pans are formed and tested before units are set. Weather tests include hose checks and negative pressure pulls where appropriate. Doors are hung on site specific frames that anticipate settlement and transport movement. When modules join, these openings align with minimal field adjustment, which speeds set day and protects the schedule.

Security and comfort rise together. Tight seals reduce smoke infiltration. Correct reveals support long term operation. Homeowners feel the difference on the first day they open a window or close a door.

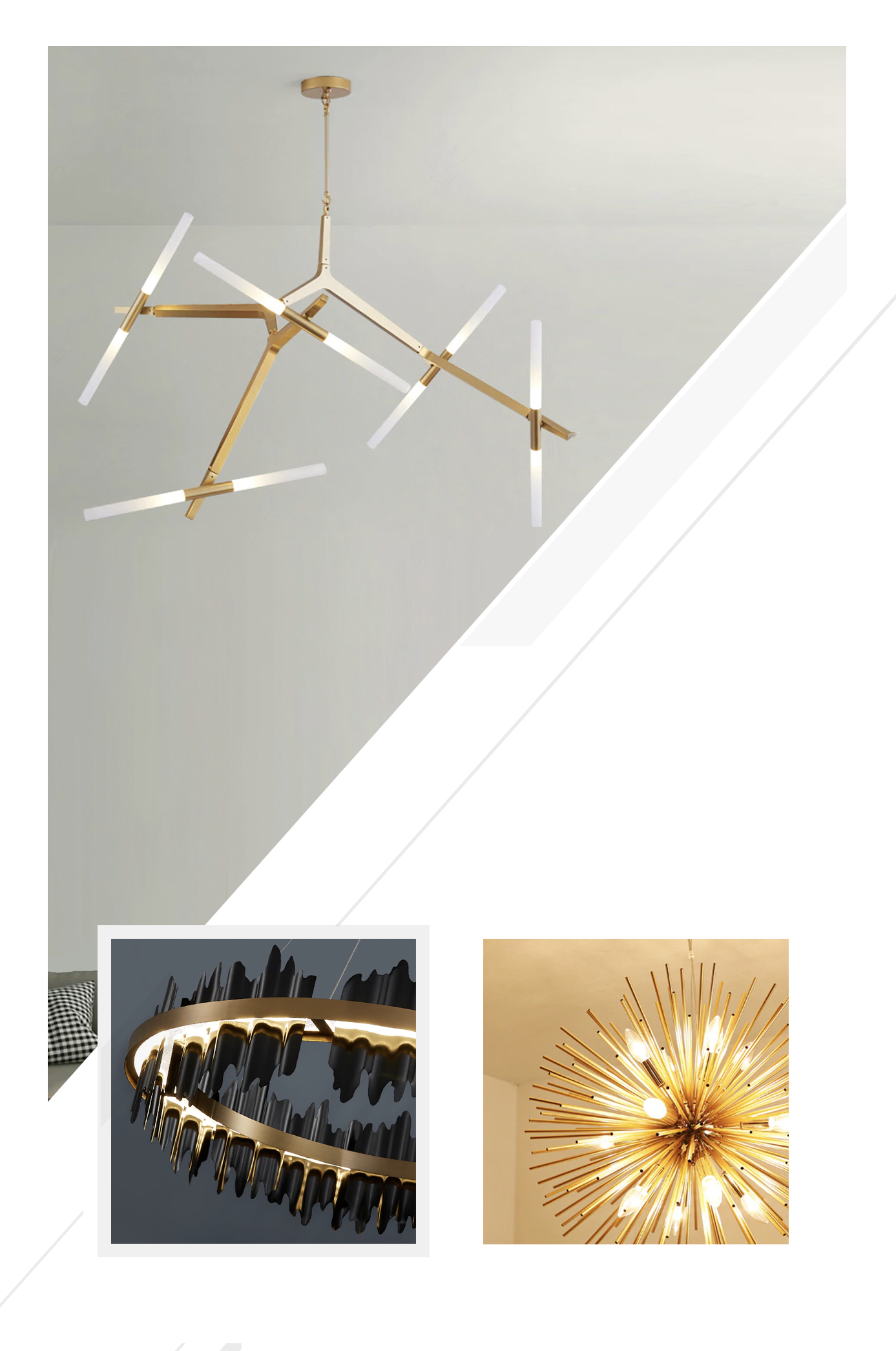

Electrical, Mechanical, and Plumbing Bench Testing

Systems are pre assembled in bright, organized bays. Electrical branches are labeled by circuit and continuity tested before walls close. Mechanical ducts are sealed and pressure tested where feasible. Plumbing lines are filled and monitored for pressure drops. Each trade signs a quality tag that follows the module to final inspection. Because testing happens indoors, there are fewer retests and less rework. Field crews focus on final connections instead of hunting for problems that started months earlier.

Placement supports safety and service. Shutoffs are accessible. Conduits are sealed where they pass the envelope. Ducts are kept in conditioned volume when possible. These choices improve performance and simplify ownership for years to come.

Documentation that Speeds Permits and Inspections

Every module ships with a digital and physical binder that includes drawings, material data, pressure tests, moisture logs, energy compliance, and photo records of critical assemblies. Plan reviewers can confirm that what they see on paper is what exists in the frame. Inspectors in Los Angeles, Ventura, Santa Rosa, Napa, and Paradise recognize organized projects and respond with efficient inspections. Clear documentation reduces questions and allows set day and final sign off to proceed smoothly.

Homeowners receive this record at handoff. It supports insurance confirmations, future improvements, and maintenance planning. A well documented home is easier to care for and easier to finance or refinance later.

Set Day: A Choreography of Safety and Speed

Factory precision shows its value when the crane arrives. Anchor points are pre located. Bolt patterns align. Roof closures and marriage walls meet without forcing. Crews move from landing to weather dry rapidly, then to air seal and finish. Streets reopen on schedule. Neighbors see a home appear in hours instead of months. For families still living in temporary housing, the psychological lift of set day is real. It marks the moment when a plan becomes a place.

Joy Line coordinates staging, traffic control, and utility clearances so set day is calm and predictable. That organization protects the community and the project timeline together.

Regional Focus: Factory Quality Meets Local Needs

Los Angeles: Hillside access and wind exposure demand tight envelopes, sealed underfloors, and careful glazing orientation. Factory built floors arrive insulated and ready to protect service runs, which shortens field work on steep lots.

Ventura: Coastal air and canyon winds call for coated fasteners, corrosion resistant finishes, and enclosed framing at decks. Factory controlled cuts and coatings extend life and reduce maintenance near the ocean.

Santa Rosa: Neighborhood rhythm matters. Consistent panel reveals, aligned window patterns, and quiet porches arrive ready for quick installation on slab foundations that pass inspection efficiently.

Napa: Rural settings benefit from large shaded outdoor rooms and non combustible hardscape within five feet of the home. Factory set door systems integrate with these spaces to support indoor outdoor living without compromising seals.

Paradise: Disturbed soils and narrow access routes favor modular approaches. Helical piles and grade beams pair with factory built modules for clean sets and minimal excavation.

Why Factory Quality Lowers Cost

Precision reduces waste and rework, which lowers cost. Dry storage prevents damage and loss. Trades move in logical sequence without idle time. Procurement locks pricing on windows, roofing, and fixtures early. Inspections occur once, indoors, instead of repeatedly outdoors. These advantages add up to predictable budgets for under insured families who need every dollar to perform. The home you receive reflects planning that protects the schedule and the bottom line.

Comfort and Health After Move In

Factory quality remains visible long after set day. Tight envelopes pair with balanced ventilation and filtration to keep indoor air cleaner during smoke events. Thermal continuity reduces hot and cold spots. Sound transmission is lower. Doors and windows operate smoothly because they were set square. Maintenance is simpler because shutoffs, panels, and cleanouts are exactly where the drawings say they are. The home functions as a calm backdrop for daily life and a resilient shelter when the weather turns.

Stories from the Line

In Los Angeles, a two module ADU rolled through framing, envelope, and finish in a steady rhythm, then set in one day on a raised steel platform. In Ventura, corrosion resistant detailing pre staged in the factory saved weeks of site time near the coast. In Santa Rosa, a single level plan with fiber cement exteriors and tempered glazing passed final without corrections. In Napa, large sliders were factory tested and installed with perfect reveals, then connected to deep porches that cool the interior. In Paradise, helical piles and factory confirmed bolt patterns created a seamless set on a narrow street.

The Joy Line Perspective

Inside the factory you can see how resilience is built. It is not an afterthought. It is measured in fastener spacing, moisture readings, window pan tests, and careful records. Joy Line Homes brings that discipline to every wildfire rebuild and ADU across California. The goal is simple. Deliver a home that protects your family, respects your budget, and arrives on a schedule you can trust. When you choose factory quality, you choose a path back to your land that feels steady, clear, and ready for the seasons ahead.

About Joy Line Homes

Joy Line Homes builds modular residences and ADUs with factory verified assemblies for WUI zones across California. Our quality control, documentation, and calm scheduling help fire affected families return home sooner in spaces that are modern, efficient, and built to last.

Visit JoyLineHomes.com to tour the process and start your rebuild plan.

Based in Santa Clara County

Tel: (831) 888-Home

Email: info@joylinehomes.com

Business Hours: 9am - 6pm