Inside the Factory: How Joy Line Homes Builds with Precision and Care

By Joy Line Homes California

When most people imagine home construction, they picture a noisy job site filled with lumber, dust, and unpredictable weather. Joy Line Homes is changing that vision entirely. Inside their modern factory, homes are built with precision, care, and consistency that traditional methods simply cannot match. Each step is guided by skilled hands and advanced technology, ensuring that every wall, frame, and finish meets the highest standards of quality.

Modular construction represents a new chapter in homebuilding—one where innovation meets craftsmanship. Joy Line Homes has perfected the process, combining efficiency with artistry to deliver homes that are as durable as they are beautiful. This is where the future of housing takes shape, one carefully constructed module at a time.

A Different Kind of Construction

Unlike traditional site-built homes, modular homes are created in a factory-controlled environment. Each module is constructed indoors, shielded from weather and external factors that can cause delays or damage. This allows Joy Line Homes to maintain full control over every phase of construction, from framing and insulation to plumbing and finishing details.

Every craftsman on the Joy Line team follows a streamlined workflow supported by digital design tools and precision machinery. Materials are stored and used efficiently, reducing waste and maintaining quality consistency from start to finish. It is a construction process that is cleaner, smarter, and far more dependable than conventional methods.

Craftsmanship Meets Technology

Inside Joy Line’s facility, advanced technology works hand in hand with human expertise. Computer-guided equipment ensures exact measurements, while skilled builders handle the details that require experience and intuition. It is a partnership between innovation and craftsmanship that creates homes built to last for generations.

Each wall, beam, and panel is carefully inspected before moving to the next stage. The attention to detail rivals high-end custom homebuilding, but with greater accuracy and speed. The factory environment transforms construction into a process of precision engineering rather than on-site improvisation.

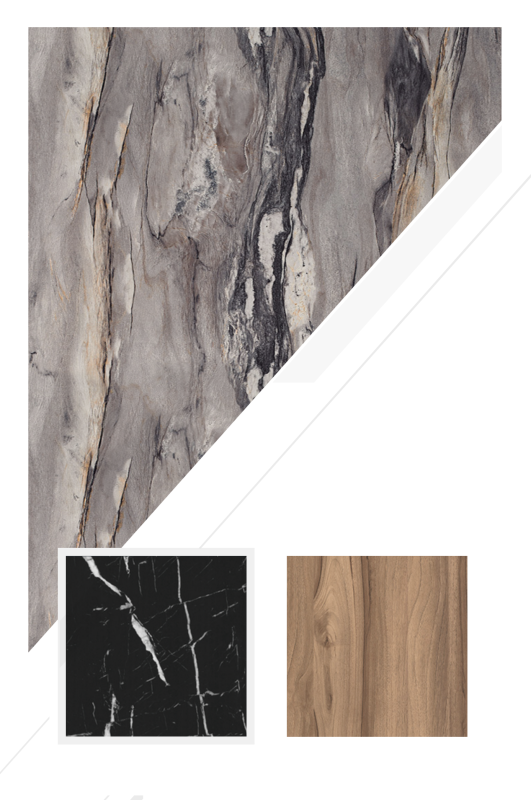

Quality You Can See and Feel

One of the key advantages of factory-built homes is consistency. Every component of a Joy Line home is built under the same conditions using the same proven methods. That means no weather damage, no rushed repairs, and no material warping caused by moisture or temperature changes. The result is a home that feels solid, balanced, and built with care.

Joy Line’s quality assurance process includes multiple inspections throughout the build. From frame alignment to insulation coverage, nothing is left unchecked. Homeowners can see the difference not just in appearance, but in long-term performance and comfort.

Sustainability Starts Here

Building in a factory also means building responsibly. Joy Line Homes minimizes waste by cutting materials precisely and recycling leftovers. Energy-efficient practices are built into the production process, including LED lighting, optimized ventilation, and efficient use of water during manufacturing.

Because materials are protected indoors, there is less waste from damage or exposure. This approach supports California’s sustainability goals while giving homeowners the benefit of a greener, more efficient home. Each Joy Line residence reflects a respect for both craftsmanship and the environment.

The Human Element

Despite the use of advanced machinery, Joy Line Homes never loses sight of the people behind the process. Skilled builders, carpenters, and engineers bring years of experience to each home. Their attention to detail ensures that every joint fits perfectly, every seam is sealed, and every finish meets Joy Line’s exacting standards.

Walking through the factory, you can sense pride in every station. Workers are not simply assembling homes—they are building the foundation of someone’s life. This care shows in the quality of the final product, which feels handcrafted even though it is factory-built.

Step-by-Step Precision

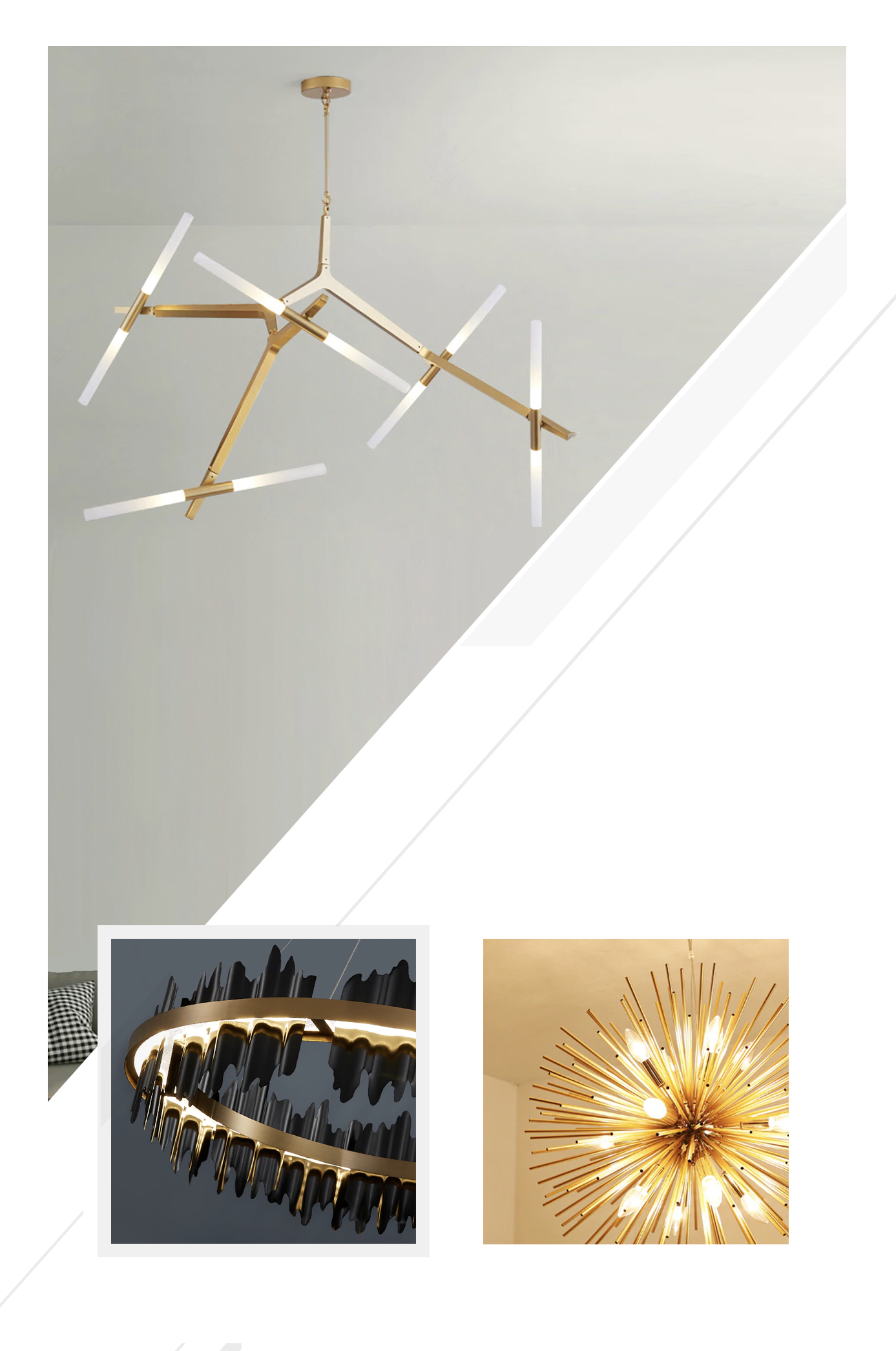

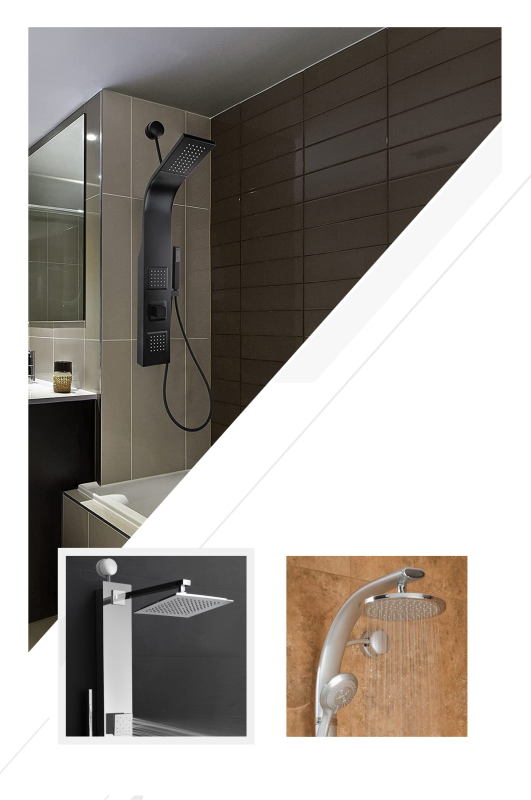

Each Joy Line home goes through a carefully planned sequence of stages. It begins with framing, where high-quality materials are measured and cut using digital precision tools. Insulation, electrical wiring, and plumbing are installed next, all within climate-controlled conditions to ensure accuracy and safety.

Finishing touches such as flooring, cabinetry, and lighting are applied before the modules are transported to the site. Once there, they are joined seamlessly to create a single unified structure. Every line, angle, and surface aligns perfectly because the factory process allows for millimeter-level precision.

Efficiency Without Compromise

Time efficiency is one of the biggest advantages of factory construction. While site preparation happens simultaneously, modules are being built indoors. This overlapping process shortens total construction time by months compared to traditional builds.

Joy Line’s process saves time without cutting corners. Every home is inspected for performance and durability before it leaves the facility. Once on-site, assembly takes days rather than months, meaning homeowners can move in faster and enjoy a home that is already tested and refined.

Built for California Conditions

California’s diverse environments—from coastal breezes to desert heat—demand homes that are resilient and adaptable. Joy Line Homes engineers each module to meet strict seismic and energy standards. Materials are selected for durability, insulation, and longevity in varying climates.

Every Joy Line home is designed to meet or exceed state building codes, ensuring safety, comfort, and efficiency. The controlled factory setting gives Joy Line the consistency needed to deliver homes that perform flawlessly across California’s wide range of conditions.

From Factory to Foundation

Once completed, each module is transported carefully to the build site, where it is assembled and secured to its foundation. The process is fast and coordinated, taking only a few days to complete. When finished, the seams between modules are invisible, creating a seamless, permanent home that looks identical to a traditional build.

The transition from factory to finished home is smooth and efficient. It showcases how precision engineering and design can come together to create beautiful, lasting structures without the stress of extended on-site construction.

Conclusion: The Craft of Modern Building

Inside the factory, Joy Line Homes is redefining what construction can be. By combining modern technology, skilled craftsmanship, and a deep commitment to quality, the company creates homes that stand apart in both design and durability. Each project reflects the care, precision, and pride of the people who build it.

For homeowners, that means peace of mind. It means knowing their home was built in the best possible conditions by a team that treats every detail as an art form. This is the Joy Line difference—a future where precision and care build homes that last for generations.

About Joy Line Homes

Joy Line Homes builds precision-crafted modular homes in California using sustainable methods, advanced technology, and the highest construction standards to create homes built with care and pride.

Visit JoyLineHomes.com to learn more about how modular homes are built with precision and purpose.

Based in Santa Clara County

Tel: (831) 888-Home

Email: info@joylinehomes.com

Business Hours: 9am - 6pm