From Factory to Foundation: How Modular Construction Saves Time and Money

By Joy Line Homes California

The future of homebuilding is changing, and it is happening faster than ever. Modular construction has transformed how homes are designed, built, and delivered. For Californians seeking efficiency, precision, and affordability, this innovative approach offers significant advantages over traditional methods. Joy Line Homes is at the forefront of this movement, delivering beautiful, high-quality modular homes from factory to foundation with remarkable speed and savings.

What once took a year or more can now be completed in a fraction of the time without compromising craftsmanship. Modular homes are redefining what it means to build smarter, greener, and more cost-effectively in today’s demanding housing market.

What Is Modular Construction?

Modular construction is a process where homes are built in sections, called modules, inside a controlled factory environment. Each module is constructed with the same building codes and materials as a site-built home but with far greater precision and efficiency. Once complete, the modules are transported to the property and assembled on a permanent foundation.

This method reduces waste, shortens build times, and improves quality control. Every component, from wall framing to electrical wiring, is inspected and tested in a stable indoor setting, free from the challenges of weather delays and inconsistent labor conditions.

Why Modular Construction Is Faster

Traditional site-built homes are exposed to unpredictable weather, material shortages, and labor scheduling issues. Modular construction avoids these pitfalls entirely. Because site preparation and module fabrication happen at the same time, total build time is cut dramatically.

| Phase | Time Saved |

|---|---|

| Design and planning | Streamlined digital coordination |

| Factory construction | 30 to 50 percent faster than on-site builds |

| On-site assembly | Completed in weeks rather than months |

In most cases, homeowners can move into their modular home within three to six months after permits are approved. The time saved translates directly into lower costs and earlier returns for property investors or families eager to settle into their new space.

Precision and Quality You Can Trust

Building indoors eliminates many of the variables that affect traditional construction. Rain, humidity, and temperature shifts can compromise framing and finishing materials. Modular construction avoids these risks entirely. Each module is built under strict quality control, ensuring every corner, seam, and joint is perfectly aligned before it leaves the factory.

Joy Line Homes uses advanced machinery and professional oversight to maintain consistency. The result is a stronger, tighter structure that performs better in energy efficiency, sound insulation, and long-term durability than many site-built homes.

How Modular Saves Money

Faster timelines and efficient processes directly reduce labor costs, material waste, and financing expenses. Because materials are purchased in bulk and stored indoors, there are no delays or damage from weather exposure. This predictable workflow allows Joy Line Homes to offer transparent pricing with fewer unexpected expenses during construction.

- Shorter construction loans and reduced interest payments

- Lower labor costs due to controlled factory scheduling

- Minimized material waste and transport costs

- Energy savings from high-performance insulation and design

By streamlining every step, modular construction delivers more value per dollar while maintaining the highest standards of craftsmanship.

The Environmental Advantage

Modular construction aligns perfectly with California’s sustainability goals. Every Joy Line home is designed to exceed energy efficiency standards, minimize waste, and reduce carbon impact. Factories recycle unused materials, optimize water use, and rely on digital precision to cut excess. The reduced need for transportation and fewer on-site activities also mean less pollution and disruption in local communities.

By choosing a modular home, homeowners contribute to a cleaner, greener future without sacrificing comfort or design quality.

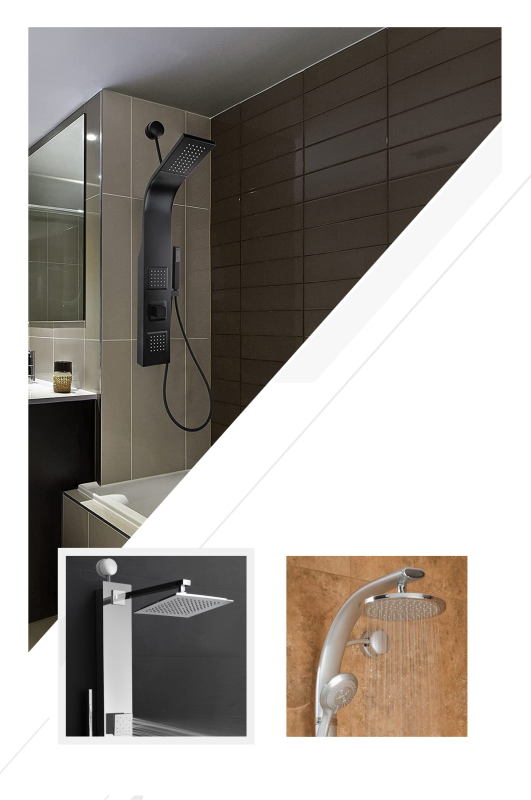

Flexibility and Customization

Modern modular homes are far from “cookie-cutter.” Homeowners can select layouts, finishes, and architectural styles that fit their needs and lifestyle. Whether you want a minimalist coastal retreat or a spacious family residence, Joy Line Homes offers modular options that reflect your personal taste while maintaining cost efficiency.

Because the design process is digital, modifications can be previewed in 3D before production begins, reducing errors and ensuring satisfaction.

Durability and Safety

Each module is engineered to withstand transport, which actually makes modular homes more structurally sound than many traditional homes. They are built to meet or exceed local seismic and wind resistance standards, an essential feature in California’s diverse climates. Joy Line Homes’ modules are inspected at every stage to ensure compliance with Title 24 energy and safety codes.

Homeowners gain peace of mind knowing their modular home is built for strength, efficiency, and longevity from day one.

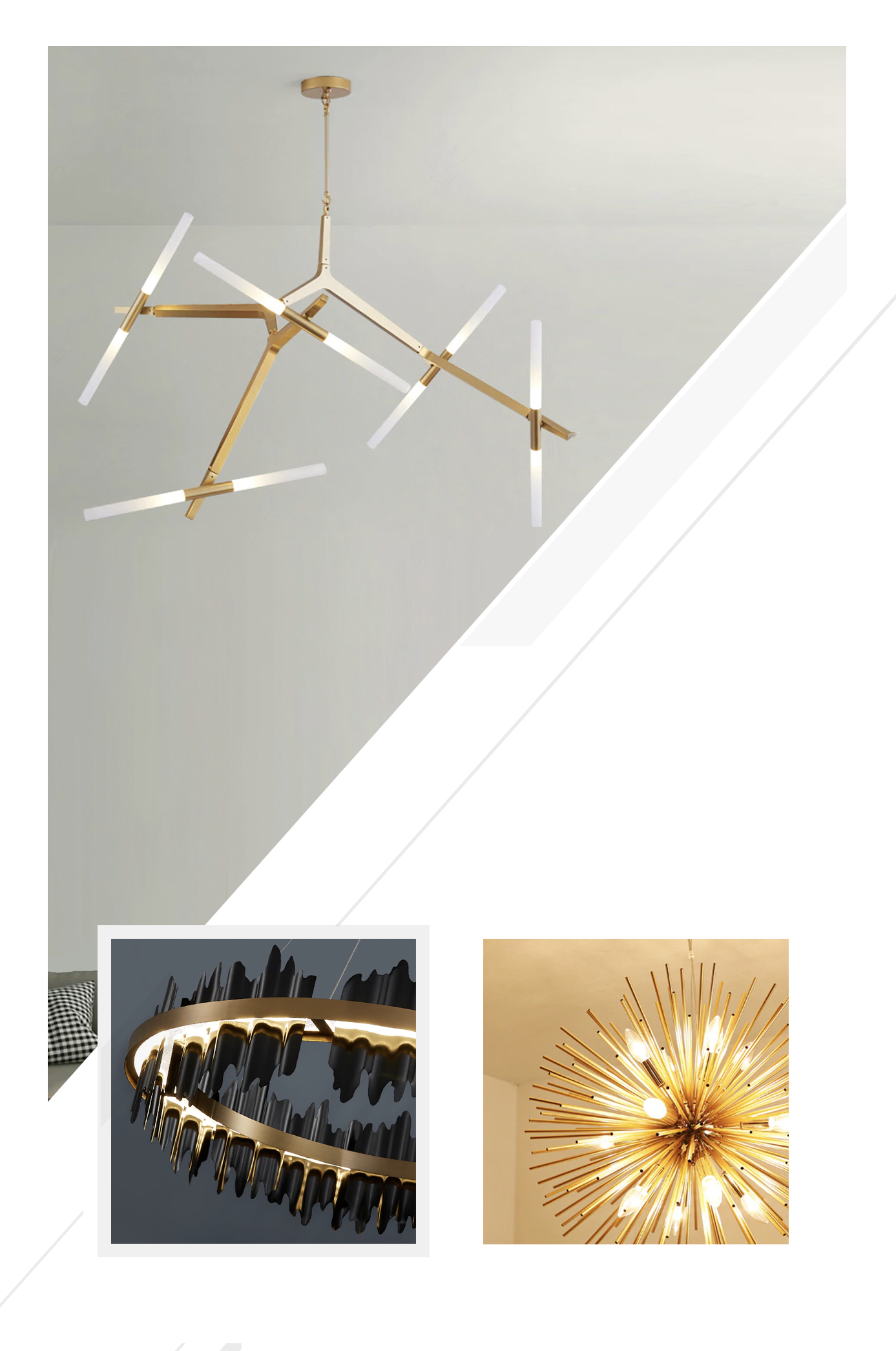

Smart Technology Integration

Efficiency extends beyond construction. Joy Line Homes incorporates smart systems into every modular design, including energy monitoring, climate control, and security features. These tools help homeowners manage energy use, reduce costs, and enjoy modern convenience from the moment they move in.

- Smart thermostats for optimized temperature control

- Automated lighting and energy monitoring systems

- High-efficiency appliances and fixtures

- Solar-ready electrical configurations

From Factory to Foundation: The Joy Line Process

Joy Line Homes manages the entire process, from initial consultation to delivery. Each project begins with a design session that captures your vision and aligns it with site conditions. Once approved, the home is built in the factory while the foundation is prepared on-site. When modules arrive, they are installed, connected, and finished in a matter of days.

This efficient process minimizes construction noise, traffic, and neighborhood disruption while maintaining a flawless finish.

| Step | Timeline |

|---|---|

| Design and permitting | 2 to 6 weeks |

| Factory build | 8 to 12 weeks |

| Delivery and installation | 1 to 2 weeks |

| Final inspection and move-in | 1 week |

From blueprint to move-in, Joy Line Homes ensures every step is efficient, transparent, and stress-free.

Conclusion: Building Smarter for a Better Future

Modular construction is transforming California’s housing industry with speed, precision, and sustainability. By building smarter, homeowners save time and money while enjoying custom designs that last. Joy Line Homes continues to lead this evolution with a commitment to quality, innovation, and environmental responsibility. From factory to foundation, every modular home represents the future of efficient, affordable, and elegant living in California.

About Joy Line Homes

Joy Line Homes specializes in modular and prefab construction that combines speed, quality, and sustainability. Based in California, we help homeowners achieve their dream homes faster, smarter, and with lower costs through innovation and craftsmanship.

Visit JoyLineHomes.com to explore our modular models and start your building journey.

Based in Santa Clara County

Tel: (831) 888-Home

Email: info@joylinehomes.com

Business Hours: 9am - 6pm