From Concept to Completion: The Journey of a Joy Line Modular Home

By Joy Line Homes California

Every Joy Line modular home begins with a simple idea—creating a space that reflects the homeowner’s lifestyle while meeting California’s standards for quality, sustainability, and efficiency. The journey from that first concept to move-in day is a carefully guided process built on expertise, precision, and collaboration.

Unlike traditional homebuilding, modular construction redefines efficiency by completing multiple phases simultaneously. Joy Line Homes manages every detail, from digital design and permitting to factory construction and final installation. This approach saves time, reduces waste, and ensures a seamless experience for homeowners from start to finish.

The Vision: Turning Ideas into Design

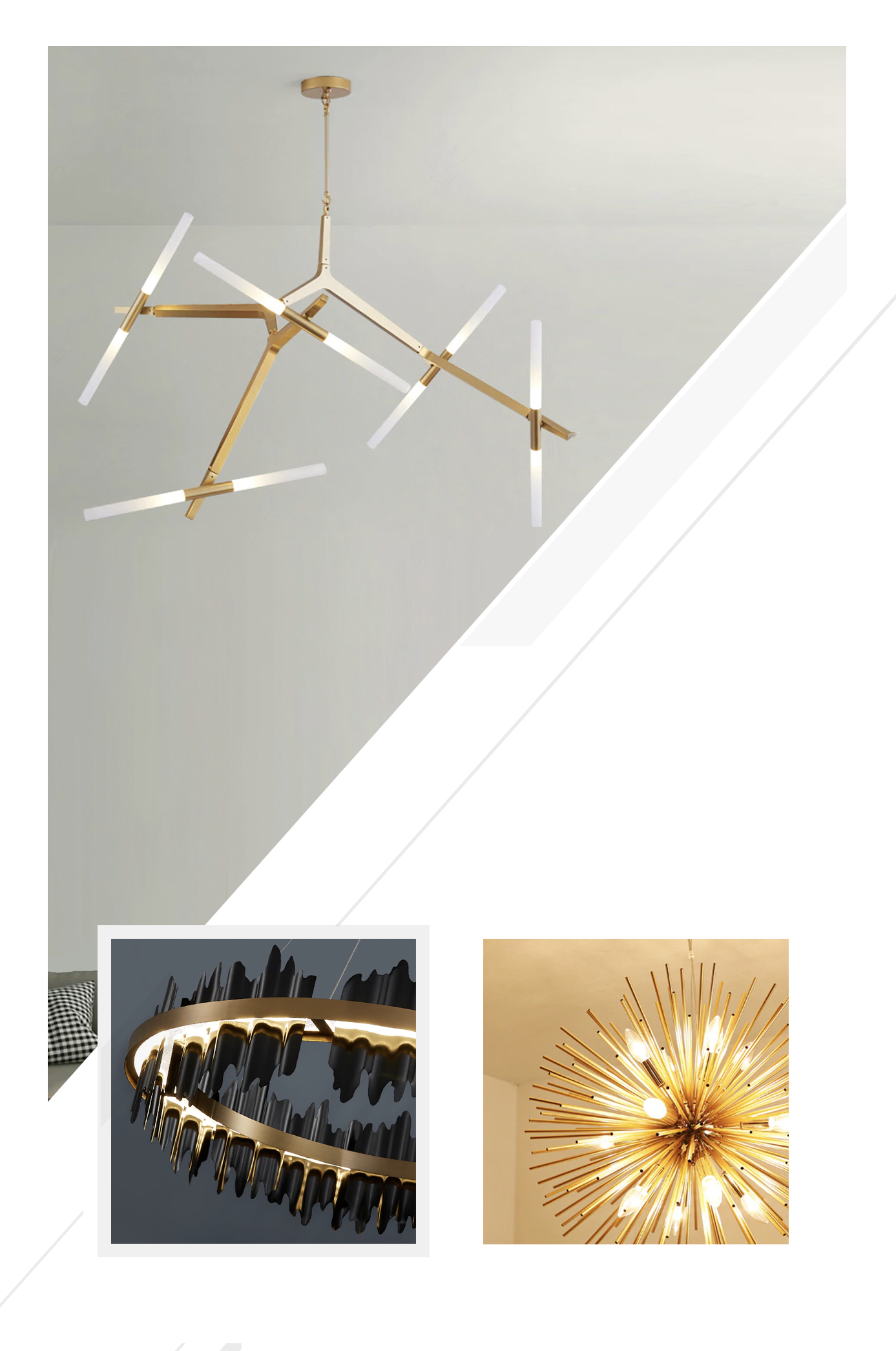

The journey begins with inspiration. Homeowners meet with Joy Line’s design team to share their vision, style, and functional needs. Whether it’s a sleek urban ADU, a family home, or a coastal retreat, the goal is to translate that vision into a modular layout that feels natural and personal.

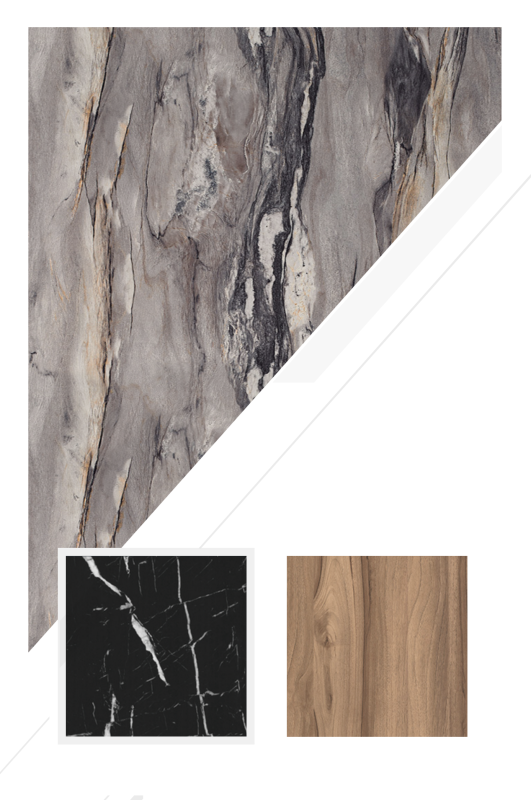

Joy Line uses advanced 3D modeling and design software to bring concepts to life. Clients can visualize floor plans, experiment with finishes, and adjust layouts before construction begins. This digital-first process ensures every design decision is thoughtful, efficient, and true to the homeowner’s taste.

Planning and Permitting: Preparing the Path

Once the design is set, Joy Line Homes handles the technical side—engineering, compliance, and permitting. Modular homes are built to the same codes as traditional homes, but factory certification often streamlines the approval process. The company’s team works directly with local building departments to ensure all requirements are met.

This phase also includes site evaluation, where land conditions, access, and utilities are reviewed. By addressing these details early, Joy Line ensures smooth coordination between the factory and on-site teams once construction begins.

Factory Construction: Building with Precision

The heart of modular innovation happens in the factory. Joy Line Homes constructs each section—or module—indoors under controlled conditions. Skilled craftsmen, engineers, and quality inspectors work side by side using state-of-the-art tools and materials to build with accuracy and consistency.

Each module is framed, insulated, wired, and finished before being transported to the site. Because construction takes place indoors, weather delays are eliminated and materials remain protected. The process also minimizes waste, making it both efficient and environmentally responsible.

Site Preparation: Setting the Stage

While the home is being built in the factory, the building site is prepared at the same time. This includes grading, utility installation, and pouring the foundation. By overlapping these phases, Joy Line Homes saves months compared to traditional timelines.

When both the site and modules are ready, the home is delivered for assembly. This parallel workflow is one of the main reasons modular construction is faster and more predictable than standard builds.

Transportation and Assembly: Bringing It All Together

Once the modules are complete, they are carefully transported to the home site. Specialized crews use cranes to position each section on the foundation with precision. Within days, the structure takes shape, walls align perfectly, and the home becomes one cohesive build.

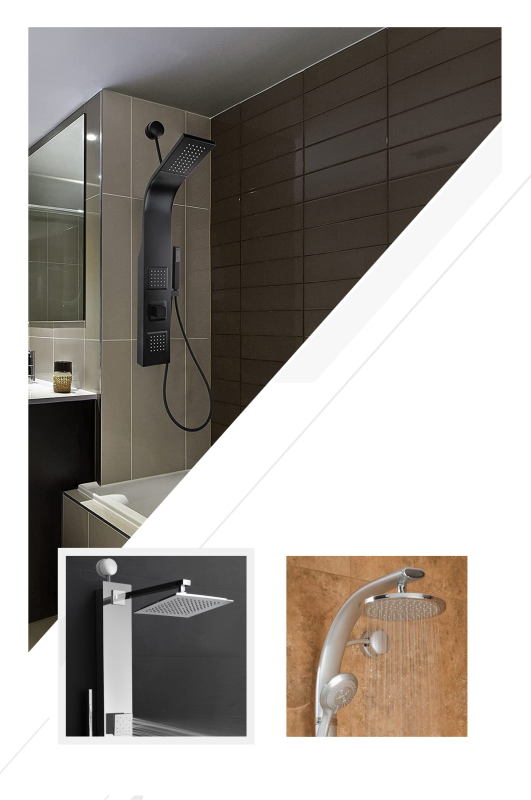

Joy Line’s team manages every aspect of this phase to ensure quality and safety. Connections for plumbing, electrical, and HVAC systems are made seamlessly, blending factory precision with on-site craftsmanship.

Finishing Touches: The Joy Line Standard

After assembly, final finishes such as roofing, painting, flooring, and landscaping are completed. Joy Line Homes conducts rigorous quality inspections to ensure every detail meets the company’s high standards. Each home undergoes multiple checks for energy efficiency, safety, and durability before being approved for occupancy.

Homeowners are kept informed through every stage, receiving progress updates and walkthroughs. Transparency is key to Joy Line’s process—it’s not just about building homes, but about building trust.

Efficiency, Sustainability, and Craftsmanship

Modular construction is known for its efficiency, but Joy Line takes it further by focusing on sustainability and craftsmanship. Energy-efficient materials, water-saving systems, and renewable energy options make every home environmentally responsible. Precision construction also means tighter seals, lower utility costs, and greater comfort year-round.

Every Joy Line modular home is a product of collaboration between technology and human skill. The blend of innovation and artistry ensures long-term value for homeowners and communities alike.

Move-In and Beyond

When the final inspection is complete, it’s time to move in. The process that began as a concept now stands as a fully realized home, ready for years of comfort and enjoyment. Joy Line Homes provides ongoing support, ensuring homeowners understand every system and feature in their new space.

For Joy Line, the end of the construction process marks the beginning of a lasting relationship with each homeowner. Every project represents more than a building—it’s a personalized experience of innovation and care.

Conclusion: A Seamless Journey to Modern Living

From the first sketch to the final key handover, Joy Line Homes has perfected the modular journey. Through careful planning, modern design, and sustainable methods, each home reflects a promise of quality and creativity. The result is a faster, cleaner, and more personalized building experience that redefines how Californians live.

Building with Joy Line Homes means joining a new era of housing—where innovation meets integrity and the homebuilding journey becomes something truly joyful from concept to completion.

About Joy Line Homes

Joy Line Homes designs and builds precision-crafted modular residences across California. Each home is a reflection of innovation, efficiency, and sustainable design built to last for generations.

Visit JoyLineHomes.com to learn more about the modular building process.

Based in Santa Clara County

Tel: (831) 888-Home

Email: info@joylinehomes.com

Business Hours: 9am - 6pm